thank you sir

its gonna be a sneaky DD  i could have gone back stock but then id be unhappy when my truck is getting passed up like im sitting still.

i could have gone back stock but then id be unhappy when my truck is getting passed up like im sitting still.

ive got a lot of things i needa pick up but i cant find the time to do it all in one day.

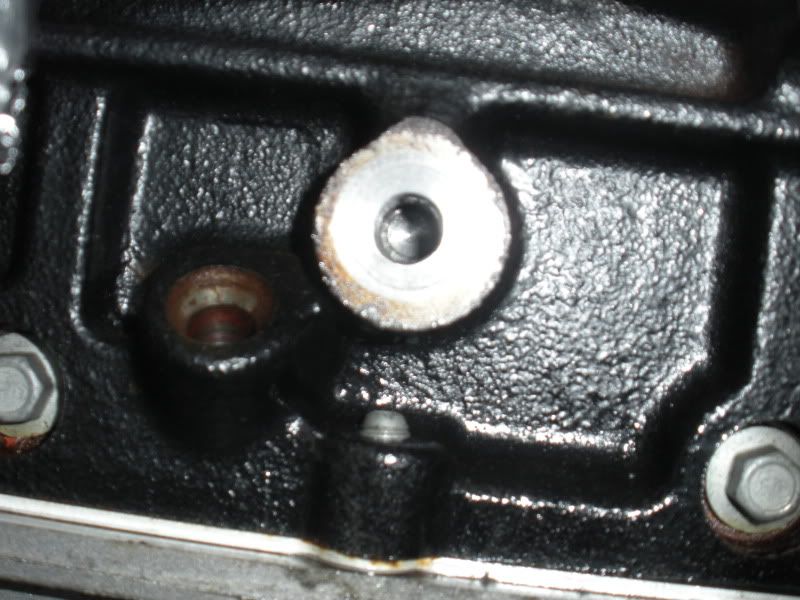

what are yall using to clean the surface of the heads an block? i dont wanna use a plastic scrapper bc its not chunks of stuff its just got a discolor to it.

ive got pics of the cam swap an knock sensors but no time to upload them just yet..maybe ill get a chance tomorrow to post em.

2008 GMC CCSB 6.2/6L80e swap

Gen IV 5.3/60e swap 1994 ecsb W/T

i could have gone back stock but then id be unhappy when my truck is getting passed up like im sitting still.

Reply With Quote

Reply With Quote

2000 Silverado ECSB- 5.3 CAI, Pacesetter LTs, ORY- Pipe, Magnaflow XL, E-fan, Ported T/B , Nelson Tuned, Built 4l60e, Circle D Stall, 3.42s G80, 2-4 Drop, Hertz Highs, Rockford 501s

2000 Silverado ECSB- 5.3 CAI, Pacesetter LTs, ORY- Pipe, Magnaflow XL, E-fan, Ported T/B , Nelson Tuned, Built 4l60e, Circle D Stall, 3.42s G80, 2-4 Drop, Hertz Highs, Rockford 501s