You can get a pulley puller from vato zone or oriellys auto for free, just rent it out. A spring compressor is extremely easy to make. Just get a pair of locking vise grip pliers and two flap pieces of metal, weld them to it as if its like a clamp. DONE>!<

a spring compressor could be made out of 3 pieces of flat bar stock since you dont have a mill to cut a relief. You'll have to use your imagination but take two equal length pieces about 5" long each and lay them flat and parallel about a half inch apart from each other. The top edge will set on the upper ledge of the cylinder head and the lower end will lay on the valve retainer. The third piece with the hole in the middle of the bar will lay across the other two bars to push the retainer down. You will need a piece of all-thread the same size as a factory rocker bolt to thread all the way down and then use a nut and washer to draw the bars down. It would be best to lay it all out and weld them together so things don't squirm. Two pieces of 1/2" square bar stock and one cross piece of 1/4" x 1" flat bar would be a pretty good start. If you can't find all thread, just get a very long bolt with a long threaded area and cut the threaded section off.

See my truck data in the "My Garage" section here... http://www.ls1truck.com/forums/my-ga...tml#post191709

SLP VALVE-SPRING-COMPRESSOR W/AIR-HOLD FITTINGS [53306] - $61.74

will this work well?

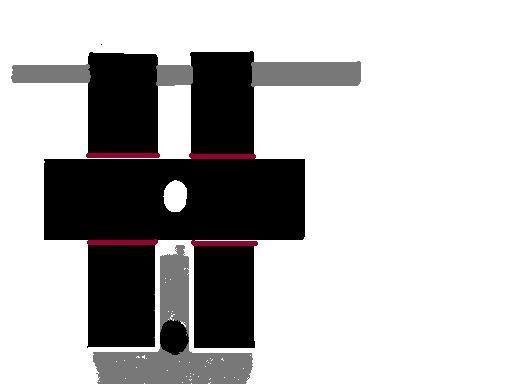

my half-assed attempt at drawing with paint

See my truck data in the "My Garage" section here... http://www.ls1truck.com/forums/my-ga...tml#post191709

^^^That's pretty good Greg! There may be a second career for you...

07 Z71 4x4, 6.0L, 3.73s, Turbonetics T76 @ 10 psi, 75 shot, Snow meth kit, PLX DM-100 wideband gauge, Nelson tune, Comp 212/216 .557/.561 114 lsa, 60# injectors, Yank 3000, 4L80E , Magnaflow - dumped, e-cutout

Line-X, Pace Edwards Full Metal Jackrabbit bedcover