ok so ive started several threads trying to figure this all out and now i finally got everything hooked up and running and here is the final HOW-TO like i promised all consolidated into this one thread.

This is to get your factory R4 compressor/bracket from your TBI motor installed on the new LS transplant for very little money. This was done on my 95. I have to note that on all the aftermarket setups ive seen, they all say 94 and prior and none for 95 up. i personally dont know what the difference is between the years but they cant be all that different so i would think this will still work for pre-95... But dont quote me on that. it should at least get you very close.

Parts needed:

Portaband/sawzal/hacksaw/grinder - any or all will do

2-1/2" hole saw

1- M10 x 1.5 x 90mm bolt (3 washers are required otherwise bolt will bottom out or you can cut tip off bolt)

1- M10 x 1.5 x 20mm bolt (i had this from some part off the LS)

1 or 2 3/4" washers

1- 995k6 serpintine belt

First we have to trim some fat off the bracket. Take out the compressor by removing the 3 retaining bolts. there is one side on the bolt head that is ground flat which will allow it to slide past the clutch. Then remove the tensioner/pulley and idler pulley and hardware. Set the idler(smaller one) and bolt/spacer aside as this will be re-used. Now cut the lower and side portions of the bracket off and discard. I have a portable band saw which makes this really simple but a hack saw or sawzawl will work too, it will just takes more time im sure.

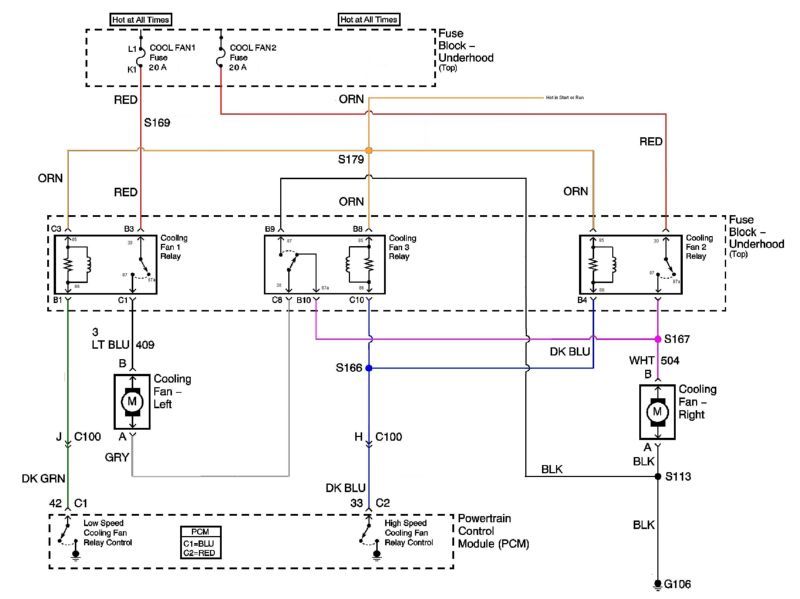

We will be using the stock LS tensioner which is in the way of the R4 bracket. So the bracket will need to be notched. This is where some of you may need to get creative. I used a hole saw (i think it was 2-1/2"). This was the most difficult part of the modifiction. I wish i could give an exact spot where to start the drill but just make sure the outside of the notch ends up close to what you see in the pic. Some touch up grinding may be necessary for clearance/adjustment. I cut all the way to the back wall of the bracket. No this dis not take away the structural integrity of it. The bracket is still very sturdy. Now just file all the sharp edges and your are ready for paint. Thats it for the bracket.

Next you will need to remove the LS tensioner off the water pump for minor trimming. Remove the pully and set it with the other idler pulley you put aside earlier. First is the extra chunk on the front which normally sits behind the grooved pully. We will be putting on the smooth idler pully from the old motor which will hit this unless cut off. again, portaband made this easy but grinder should work also.

You can see where i cut.

Plenty of clearance now.

Next will be to trim the little tab on the back down just a bit. I think its a support tab so i left that little bit left to help out.

We need to make a support brace next. It will be going from the pump bracket to the head. at the moment i am only using one brace and it seems to be very strong. but there is some vibration when the pump is running and i will probably be putting one going rearward and mounting it to a bolt hole on the side of the head. you may want to do this also but that is up to you as it works fine without it. i have all kinds of scrap metal laying around so i dug through and found a piece of 3/16-1/4" flat stock. i cut it around 6" long, drilled a hole in each end for the bolts and put about a 7/8" offset in it.

the third hole in the middle was already in the scrap steel but it doesnt affect anything.

Thats all the fabrication required. Now its time to install everything. First is to take the 20mm-ish bolt, put it through one end of your support brace and into the far right bolt hole in the head. This is much easier to do before pump bracket is in place. Dont tighten yet. Now take the 90mm bolt (and washers if you didnt cut tip off bolt) and put it through right side hole in pump bracket and into top left bolt hole in head as shown. Again do not tighten yet.

this is the reason for the huge notch. Fits nicely around the tensioner.

Next set the compressor in the bracket and push the 3 long bolts through. slip the support brace over the bolt and install the 3 nuts. All the hardware can now be tightened down. heres a bad pic of the support brace...

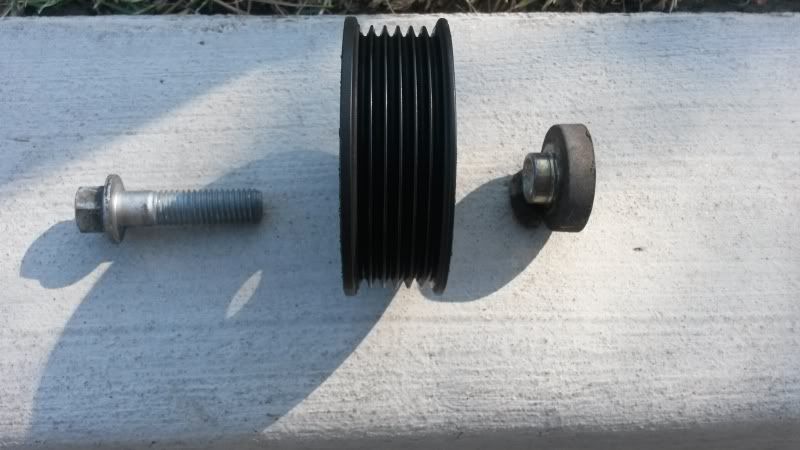

You can now put the pullies back on But you will be reversing them. The bearings are the same size. The smooth smaller TBI pulley goes on the LS tensioner. you might need 1 or 2 3/4" washers depending on thickness to space the pulley forward a bit. Mine was still slightly touching the tensioner. You will be re using the LS bolt but the front washer will be from the TBI pulley. This is the order:

This is the washer i had that slipped right over the boss.

Now put the LS grooved pulley on the R4 bracket where the smooth idler used to go. you will be using the TBI bolt and rear spacer and NO front washer. Its not needed. this is the order:

Last but not least is the Belt which took me 2 days of trial and error to figure out. Now this belt will work with the setup i have just mentioned. but if you change things, the belt will have to be changed as well. I ended up with autozone duralast part #995k6. i didnt want to get an expensive one in case things didnt line up and it ate the belt. So far so good. i dont notice any unusual wear and it doesnt slip at all. so i think you would be alright to go with a better brand as long as its the same length but thats your choice. Follow the belt in the pics for the propper re-routing i came up with:

The coolant hose gets super close to the belt and would flop around and started cutting into the hose. so a support will need to be made.

the support i made but im sure you can figure something out depending on your setup.

the stock hoses SHOULD work as the compressor is in almost the exact same position so modification of the hoses shouldnt be nesessary. But due to the location of my PCM and fuse block, i had to get my lines modified. Here is a pic for reference:

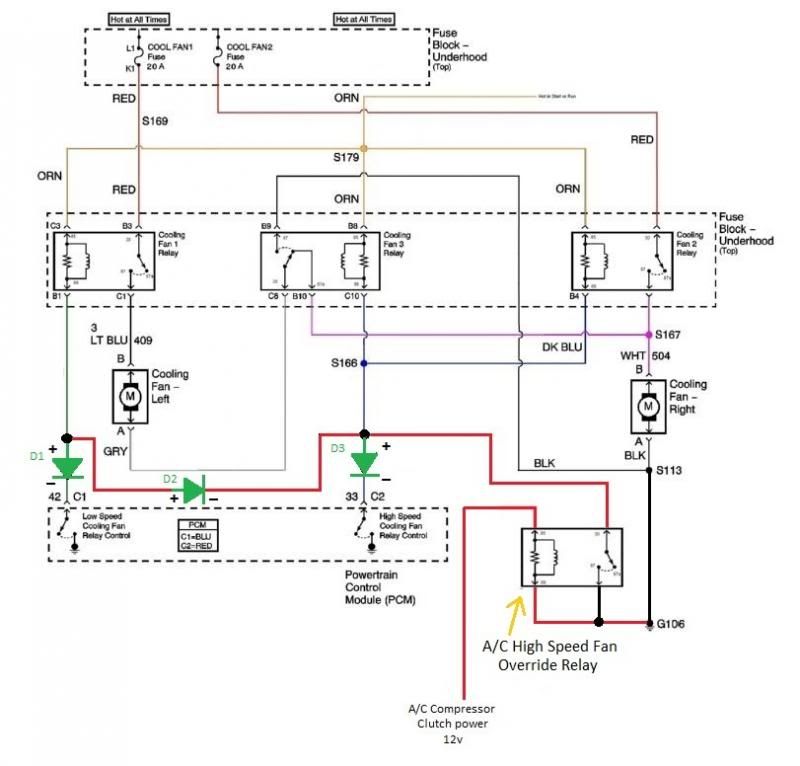

Im pretty sure that is all to get it mounted and running. If i remember something i will update. Next post will be for those running electric fans and how to hook them up to work with the AC.

Reply With Quote

Reply With Quote